News

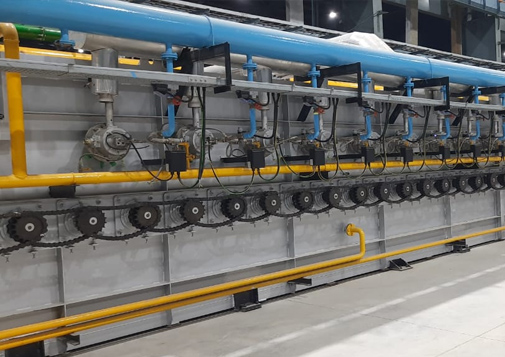

Successfully commissioned Pre-Heat Ovens for Rashmi Seamless

Successfully commissioned Post-Heat Ovens for Rashmi Seamless

We are pleased to have successfully commissioned 2 nos. Post-Heat Ovens, for Rashmi, for heating of low carbon steel pipes.

Each oven is of 180 MT/hr capacity, and pipes are heated indirectly, through Hot Air Generators.

Successfully commissioned a Mesh-Belt Conveyor Furnace for DSRV

We are pleased to have successfully commissioned a Mesh-Belt Conveyor Furnace, for DSRV, for bright annealing of carbon steel tubes.

The furnace capacity is 250 kg/hr.

Currently executing an order for Bell Annealing Furnaces for Tube Investments

We are pleased to have recently received an order for Bell Annealing Furnaces, along with associated equipment, from Tube Investments, for bright annealing of stainless steel strip coils in hydrogen atmosphere.

The installation will comprise of 6 nos. Annealing Bases, 6 nos. Inner Covers, 4 nos. Heating Hoods, 3 nos. Cooling Hoods, Valve Stands, MCC and PLC System The equipment will be designed for production capacity of 78,000 MT/annum.

Charge stack will be of 2,200 mm diameter and 5,600 mm height. Maximum charge stack weight will be 120 MT. Fuel will be natural gas / LPG, and the combustion system will be on pulse-firing basis.

This is a repeat order from Tube Investments, of Bell Annealing Furnaces. This is the best compliment that we can receive from Tube Investments.

Manufacturing activities are going on presently.

Successfully commissioned a Roller Hearth Furnace for Tube Investments

We are pleased to have successfully commissioned a Roller Hearth Furnace, for Tube Investments, for bright annealing of carbon steel tubes.

The furnace capacity is 6 MT/hr, and it is suitable for propane gas firing.

This is a repeat order from Tube Investments, of Roller Hearth Furnace. This is the best compliment that we can receive from Tube Investments.

Successsfully commissioned Bell Annealing Furnaces for A-One

We are pleased to have successfully commissioned Bell Annealing Furnaces, along with associated equipment, for A-One Gold, for bright annealing of stainless steel strip coils in hydrogen atmosphere.

The installation comprises of 2 nos. Annealing Bases, 2 nos. Inner Covers, 1 no. Heating Hood, 1 no. Cooling Hood, Valve Stands, MCC and PLC System The equipment is designed for production capacity of 48,000 MT/annum.

Charge stack is of 2,050 mm diameter and 5,400 mm height. Maximum charge stack weight is 105 MT. Furnace is electrically-heated.

Successfully supplied automation and control equipment to Arora Iron

We are pleased to have received an order from Arora Iron, for supply of automation and control equipment for their existing Pusher Furnace.

The order has been successfully completed, and the customer is happy with our prompt service.

Currently executing an order for Bell Annealing Furnaces for Theis Precision

We are pleased to have recently received an order for Bell Annealing Furnaces, along with associated equipment, from Theis Precision, for bright annealing of stainless steel strip coils in hydrogen atmosphere.

The installation will comprise of 4 nos. Annealing Bases, 4 nos. Inner Covers, 2 nos. Heating Hoods, 2 nos. Cooling Hoods, Valve Stands, MCC and PLC System The equipment will be designed for production capacity of 64,000 MT/annum.

Charge stack will be of 1,850 mm diameter and 5,600 mm height. Maximum charge stack weight will be 85 MT. Fuel will be natural gas / LPG, and the combustion system will be on pulse-firing basis.

Manufacturing activities are going on presently.

Currently executing an order for Bell Annealing Furnaces for JSW

We are pleased to have recently received an order for Bell Annealing Furnaces, along with associated equipment, from JSW, for spherodizing of alloy steel wire coils in nitrogen atmosphere.

The installation comprises of 5 nos. Annealing Bases, 5 nos. Inner Covers, 3 nos. Heating Hoods, 2 nos. Cooling Hoods, Valve Stands, MCC and PLC System. The equipment is designed for production capacity of 28,000 MT/annum.

Charge stack is of 3,600 mm diameter and 4,000 mm height. Maximum charge stack weight is 30 MT.

Furnace is electrically-heated. The furnace is designed for 850 °C maximum temperature.

Commissioning activities are going on presently.

Successfully commissioned a Vertical Split-type Furnace for L&T (for ISRO)

We are pleased to have successfully commissioned a Vertical Split-type Furnace, for L&T (for ISRO), for ageing / maraging of steel shells.

The furnace capacity is 6.5 MT, and it will be suitable for electrical-heating.

More information cannot be shared, due to this project being of a highly confidential and sensitive nature.

Successfully commissioned a Roller Hearth Furnace for Lal Baba Seamless

We are pleased to have successfully commissioned a Roller Hearth Furnace, for Lal Baba Seamless, for spherodizing of steel tubes.

The furnace capacity is 1 MT/hr, and it is suitable for electrical-heating.

This is a repeat order from Lal Baba Seamless, of Roller Hearth Furnace. This is the best compliment that we can receive from Lal Baba Seamless.

Successfully commissioned a Roll-Down Furnace for Lal Baba Seamless

We are pleased to have successfully commissioned a Roll-Down Furnace for reheating of steel rounds, for Lal Baba Seamless.

The Furnace is of 4 MT/hr capacity, and is suitable for firing with LPG.

Successfully commissioned a Walking Hearth Furnace for Rashmi

We are pleased to have successfully commissioned a Walking Hearth Furnace, for Rashmi.

The furnace capacity is 6 MT/hr, and it is suitable for LDO-firing, as well as cold and clean PG.

The furnace is going to be used for reheating of low and medium carbon steel rounds.

This is a repeat order from Rashmi, of Walking Hearth Furnace. This is the best compliment that we can receive from Rashmi.

Successfully commissioned a Walking Hearth Furnace for Rashmi

We are pleased to have successfully commissioned a Walking Hearth Furnace, for Rashmi.

The furnace capacity is 6 MT/hr, and it is suitable for LDO-firing, as well as cold and clean PG.

The furnace is going to be used for reheating of low and medium carbon steel rounds.

This is a repeat order from Rashmi, of Walking Hearth Furnace. This is the best compliment that we can receive from Rashmi.

Successfully commissioned a Walking Hearth Furnace for Rashmi

We are pleased to have successfully commissioned a Walking Hearth Furnace, for Rashmi.

The furnace capacity is 4 MT/hr, and it is suitable for LDO-firing, as well as cold and clean PG.

The furnace is used for reheating of low and medium carbon steel rounds.

Currently executing an order for a Roller Hearth Furnace for Tubekraft USA

We are pleased to have recently received an order for a Roller Hearth Furnace, from Tubekraft, USA, for bright annealing of carbon steel tubes.

The furnace capacity will be 1.5 MT/hr, and it will be suitable for natural gas firing.

Manufacturing activities are going on presently.

Successfully commissioned Bell Annealing Furnaces for Jindal United Steel

We are pleased to have successfully commissioned Bell Annealing Furnaces, along with associated equipment, for Jindal United Steel, for bright annealing of stainless steel strip coils in hydrogen atmosphere.

The installation comprises of 4 nos. Annealing Bases, 4 nos. Inner Covers, 2 nos. Heating Hoods, 2 nos. Cooling Hoods, Valve Stands, MCC and PLC System The equipment is designed for production capacity of 54,500 MT/annum.

The Application Software, control philosophy and engineering details for the Project are developed jointly with Autodata, our Channel Partners.

This is a repeat order from Jindal United Steel, of Bell Annealing Furnaces. This is the best compliment that we can receive from Jindal United Steel.

Successfully commissioned fuel conversion of Walking Hearth Furnace at Vardhman Special Steel

We are pleased to have successfully commissioned fuel conversion of existing Walking Hearth Furnace for Vardhman Special Steel.

The furnace is of 33 MT/hr capacity, and will now be suitable for firing with natural gas / HFO.

Successfully commissioned a Roller Hearth Furnace for TI Group

We are pleased to have successfully commissioned a Roller Hearth Furnace for TI Group, for bright annealing of carbon steel tubes.

The furnace capacity is 3 MT/hr, and it is suitable for propane / NG-firing.

This is a repeat order on us, and it is the best compliment we could ever receive from TI Group.

Appointed Mr. Anup Gosavi as Senior Project Manager – Projects

We are pleased to announce that Mr. Anup Gosavi has joined our Company as Senior Manager – Projects. We welcome him into our family, and look forward to many years of doing some good work together.

In his current role, he is looking after Reheat Furnaces projects.

He has over 16 years of previous experience in exactly the same type of Projects, and will surely be an asset to our Company.

Successfully commissioned a Pusher Reheat Furnace for ISWP (Tata Steel)

We are pleased to have successfully commissioned a Pusher Furnace for reheating of steel billets, for ISWP (Tata Steel).

The Furnace is of 55 MT/hr capacity, and is suitable for firing with natural gas / HFO.

Korus Engineering Solutions are the Consultants for the Project.

We are pleased to have successfully commissioned 2 nos. Pre-Heat Ovens, for Rashmi, for heating of low carbon steel pipes.

Each oven is of 180 MT/hr capacity, and pipes are heated indirectly, through Hot Air Generators.